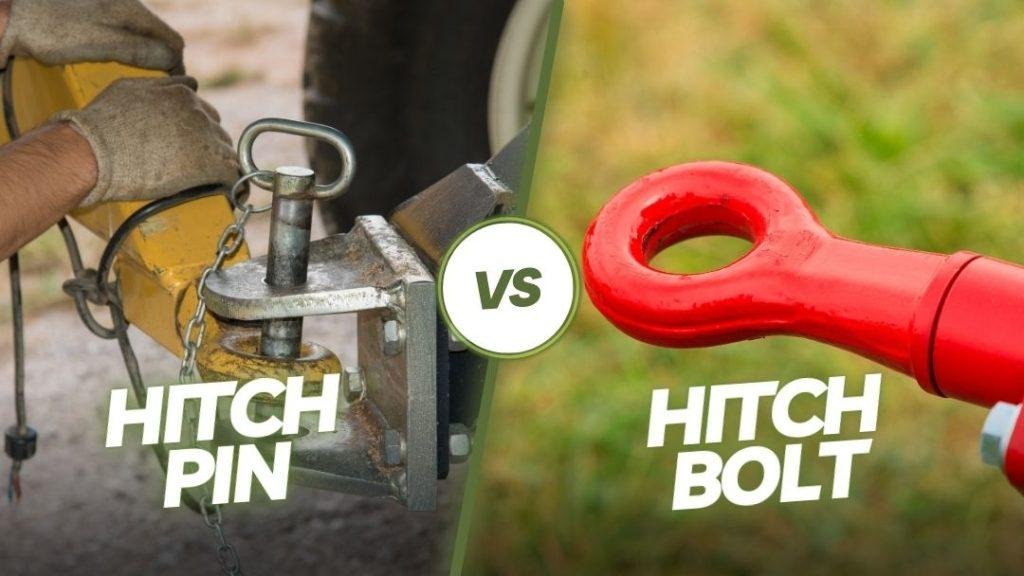

Hitch pins are used to secure a trailer hitch to a vehicle, while bolts are used to fasten two or more objects together. We will discuss the differences between hitch pins and bolts, including their uses, advantages, and disadvantages.

Additionally, we will explore the various types of hitch pins and bolts available in the market and provide some tips for choosing the right option for your needs. Whether you are a trailer owner or a diy enthusiast, understanding the distinctions between hitch pins and bolts can help you make informed decisions when it comes to securing and connecting objects.

Advantages Of Hitch Pins

Hitch pins offer numerous advantages over bolts, including easy installation and removal, versatility in various applications, and a secure connection. Their simplicity and reliability make them a preferred choice for connecting equipment and trailers.

Hitch pins are versatile fasteners widely used in various industries for their ease of installation and removal, as well as their cost-effectiveness. Let’s explore the advantages of hitch pins in detail:

Easy Installation And Removal:

- Quick and hassle-free: Hitch pins offer a straightforward installation process, allowing you to secure and release attachments swiftly.

- Convenient locking mechanism: These pins feature a simple and reliable locking mechanism that ensures a secure hold.

- No additional tools required: You can easily install or remove hitch pins without the need for any specialized tools, making it a convenient choice for users.

Versatile Applications In Various Industries:

- Agriculture: It’s commonly used in agricultural equipment such as tractors, tillers, and spreaders to connect implements securely.

- Construction: Hitch pins find applications in construction machinery like excavators, loaders, and bulldozers, providing a reliable connection for attachments.

- Automotive: Hitch pins are essential for towing, connecting trailers, and other towing accessories, making them a vital component in the automotive industry.

- Material handling: These versatile pins are commonly used in material handling equipment like forklifts, cranes, and hoists to secure loads efficiently.

Cost-Effective Option:

- Affordable alternative: Hitch pins are a cost-effective choice compared to alternatives, such as bolts or clips, making them a preferred option for many users.

- Durable and reusable: Made from sturdy materials like steel, hitch pins are durable and can withstand heavy loads, ensuring long-term use.

- Reduced maintenance costs: Due to their simple design, hitch pins typically require minimal maintenance, resulting in cost savings over time.

Hitch pins provide easy installation and removal, making them convenient for users. Their versatility allows for applications across various industries, including agriculture, construction, automotive, and material handling. Additionally, these pins offer a cost-effective solution that is durable and reusable, minimizing maintenance expenses.

So, whether you need to secure attachments, tow trailers, or handle materials, hitch pins are a reliable and efficient choice.

Disadvantages Of Hitch Pins

Hitch pins have their disadvantages when compared to bolts. They may come loose easily and are not as secure, especially for heavy loads. Bolts provide a stronger and more reliable connection for towing purposes.

Hitch pins, while commonly used for securing attachments and implements to a tractor or other machinery, have their share of disadvantages. It is important to understand these limitations before deciding on the most suitable fastening option. Let’s delve into the drawbacks of hitch pins:

Limited Strength And Load-Bearing Capacity:

- Hitch pins may have a lower load-bearing capacity compared to bolts. They are typically designed for lighter applications and may not be able to withstand heavy loads. This limitation could pose a potential risk when using hitch pins for heavy-duty tasks.

- In situations requiring significant strength, the limited capacity of hitch pins can compromise the overall stability and safety of the attachment. The potential for failure under heavy loads makes it crucial to consider alternate fastening options with higher strength ratings.

Prone To Accidental Disengagement:

- One major disadvantage of hitch pins is their susceptibility to accidental disengagement. Due to the design and mechanics of hitch pins, there is a higher risk of unintentional detachment during operation. This poses a safety hazard, particularly when working with moving machinery.

- Vibrations, jolts, and sudden impacts can jar the hitch pin loose, leading to equipment instability or detachment. To minimize the risk of accidental disengagement, it is advisable to double-check the tightness of the hitch pin before and during usage.

Not Suitable For Heavy-Duty Applications:

- Hitch pins are generally not suitable for heavy-duty applications that require increased strength and load-bearing capacity. Their design and construction make them more suitable for lighter-duty tasks or non-critical attachments.

- When it comes to heavy machinery or equipment that undergoes high levels of stress, a more robust fastening option, such as bolts and nuts, should be considered. Bolts provide greater strength, stability, and reliability in such demanding applications.

While hitch pins are often used due to their simplicity and ease of use, they come with their fair share of disadvantages. Their limited strength and load-bearing capacity can restrict their suitability for heavy-duty tasks. Additionally, the risk of accidental disengagement makes it essential to exercise caution when relying solely on hitch pins for attachment security.

Advantages Of Bolts

Bolts offer distinct advantages over hitch pins, providing secure fastening for a range of applications. With their durable construction and reliable performance, bolts ensure stability and strength, making them a preferred choice for many industries.

When it comes to securing and fastening objects, bolts have several advantages over hitch pins. Let’s explore the key benefits of using bolts in various applications:

High Strength And Load-Bearing Capacity

- Bolts are known for their exceptional strength and load-bearing capacity, making them perfect for heavy-duty tasks. Whether you’re assembling equipment or constructing structures, bolts provide the necessary support and stability.

- Their high tensile strength ensures that they can withstand intense pressure and heavy loads without breaking or loosening over time.

- Bolts can endure vibration and other dynamic forces, making them reliable for long-term use in demanding environments.

- The use of high-quality materials in manufacturing bolts enhances their durability, allowing them to withstand harsh conditions and maintain their strength.

Secure And Reliable Fastening

- Bolts offer a secure and reliable fastening solution, ensuring that objects remain firmly in place. Their threaded design allows for a tight and permanent connection, minimizing the risk of loosening or accidental disassembly.

- With their ability to provide even pressure distribution, bolts effectively prevent objects from shifting or moving, enhancing overall safety.

- When properly installed and tightened, bolts create a locked connection that reduces the chances of theft or tampering.

- The use of nuts and washers with bolts adds an extra layer of security, preventing unintended loosening and promoting stability.

Ideal For Heavy-Duty Applications

- Due to their high strength and load-bearing capacity, bolts are ideal for heavy-duty applications. They can withstand extreme forces and stress, making them suitable for scenarios where safety and reliability are paramount.

- Bolts find extensive use in industries such as construction, manufacturing, automotive, and aerospace, where they are required to hold together large structures or components.

- Heavy machinery, equipment, and infrastructure often rely on bolts to ensure their structural integrity and operational efficiency.

- The versatility of bolts allows them to support a wide range of materials, including metals, wood, and plastics, further adding to their appeal in heavy-duty applications.

Bolts provide numerous advantages over hitch pins when it comes to strength, load-bearing capacity, secure fastening, and suitability for heavy-duty applications. Their reliability, durability, and ability to withstand intense forces make them a popular choice in various industries. So, if you’re looking for a robust and dependable fastening solution, bolts are an excellent choice.

Disadvantages Of Bolts

Bolts are not without their disadvantages when compared to hitch pins. While bolts offer a secure connection, they can be time-consuming to install and require additional tools for installation and removal. Additionally, bolts may be prone to rust and corrosion over time, reducing their effectiveness.

When it comes to hitch pins versus bolts, it’s important to consider the drawbacks of using bolts for trailer hitch applications. While bolts certainly have their advantages, there are several disadvantages to keep in mind. Let’s take a closer look at three key areas where bolts may fall short.

Complex Installation Process:

- Requires pre-drilling: Unlike hitch pins, which can simply be inserted into a pre-drilled hole, bolts require pre-drilling. This adds an extra step to the installation process and may require additional tools and expertise.

- Alignment challenges: Achieving proper alignment during installation can be challenging with bolts. The process may involve aligning multiple parts correctly, which can be time-consuming and requires precision.

- Nut tightening: Bolts need to be secured with nuts that require tightening. This can be difficult, especially in tight spaces or when working with heavier loads.

Time-Consuming Removal Procedure:

- Unscrewing process: When it’s time to remove a bolted hitch, you’ll need to unscrew each bolt individually. This can be a time-consuming process, especially if there are multiple bolts to remove.

- Corrosion and rust: Over time, bolts may become corroded or rusted, making removal even more challenging. The added effort required to remove rusted bolts can prolong the removal procedure significantly.

- Potential damage: Removing bolts may involve using force or specialized tools, which could potentially damage the vehicle or trailer hitch if not done carefully. This risk of damage adds another layer of complexity to the removal process.

Higher Cost Compared To Hitch Pins:

- Material and manufacturing costs: Bolts typically require higher-quality materials and more intricate manufacturing processes compared to hitch pins, resulting in higher production costs.

- Additional components: Bolts necessitate the use of nuts and washers, which come with their own costs. This makes the overall cost of using bolts higher compared to the simple design of hitch pins.

- Potential for replacement: If bolts become damaged or worn over time, they will need to be replaced entirely. This additional cost of replacement can add up over the lifetime of using bolts for trailer hitch connections.

While bolts offer certain advantages, such as greater security and stability, they also come with some notable disadvantages. The complex installation process, time-consuming removal procedure, and higher cost compared to hitch pins should be taken into consideration when deciding which option is best suited for your needs.

Strength And Load-Bearing Capacity

Hitch pins offer reliable load-bearing capacity, making them ideal for securing heavy loads. Bolts, on the other hand, provide strength and stability, ensuring a secure connection. Choose the right option based on your specific needs.

Hitch Pin Limitations

A hitch pin is a simple and convenient tool for securing various types of connections, such as trailer couplers, tow bars, and agricultural implements. However, it’s important to be aware of the limitations of hitch pins, particularly when it comes to strength and load-bearing capacity.

Here are a few points to consider:

- Strength limitations:

- Hitch pins are typically made of steel, which provides decent strength but may not be suitable for extremely heavy-duty applications.

- The diameter and thickness of the hitch pin also play a crucial role in determining its strength. Thicker and larger pins tend to offer better load-bearing capacity and are more suitable for heavy loads.

- Load-bearing capacity limitations:

- The load-bearing capacity of a hitch pin depends on various factors, including the type of material it is made of, its diameter, and the overall design.

- While hitch pins can handle moderate loads, they may not be suitable for extremely heavy or constant loads. Using them beyond their load-bearing capacity can lead to bending or breaking, which can compromise the safety and security of your connections.

Bolt Advantages In Heavy-Duty Applications

When it comes to heavy-duty applications, bolts have several advantages over hitch pins. Here’s why bolts are often preferred in such scenarios:

- Enhanced strength and durability:

- Bolts are typically made of high-grade steel, offering superior strength and durability compared to hitch pins.

- The threading of bolts allows for a snug fit, ensuring a secure connection that can withstand heavy loads and vibrations.

- Increased load-bearing capacity:

- Bolts, especially those designed for heavy-duty applications, are capable of handling significantly higher loads compared to hitch pins.

- The larger diameter and stronger construction of bolts make them more suitable for supporting heavy weights and enduring consistent strain.

- Flexibility in size and configurations:

- Bolts come in various diameters, lengths, and head types, providing greater options to accommodate specific load requirements.

- Additionally, bolted connections can be customized by using washers, nuts, and other accessories to enhance strength and load-bearing capacity.

In heavy-duty applications, where strength and load-bearing capacity are crucial, bolts offer superior performance compared to hitch pins. It’s important to choose the right fastening solution based on the specific requirements of your project to ensure safety and reliability.

Ease Of Installation And Removal

Comparing the ease of installation and removal, a hitch pin offers quick and hassle-free attachment, while a bolt requires more time and effort. Simplify your towing experience with the convenience of a hitch pin.

Hitch Pin Simplicity

Installing and removing a hitch pin is a straightforward process that requires minimal effort. Here’s a breakdown of the ease of installation and removal when using a hitch pin:

- Simply insert the hitch pin into the receiver tube of your trailer hitch.

- Slide the accompanying clip or lock into place to secure the pin.

- To remove the pin, just remove the clip or lock and slide the pin out.

Bolt Complexity And Time Requirements

Using a bolt for installation and removal can be a more complex and time-consuming task compared to a hitch pin. Consider the following points regarding the complexity and time requirements when using a bolt:

- Bolt installation involves aligning the hitch and trailer holes, which can be challenging at times.

- Once aligned, the bolt needs to be threaded through both the hitch and trailer, requiring extra time and effort.

- Tightening the bolt securely may need additional tools such as wrenches or ratchets.

- Removing a bolt involves reversing the installation process, including undoing the threading and alignment.

While a hitch pin offers simplicity and quick installation or removal with just a few steps, using a bolt can be more complex and time-consuming, requiring alignment, threading, and extra tools. Consider these factors when deciding which option best fits your needs.

Durability And Reliability

Durability and reliability are key factors to consider when comparing a hitch pin to a bolt for securing your trailer. The hitch pin offers a secure and dependable solution, while the bolt provides added strength and resistance. Choose the option that best meets your needs for a long-lasting and reliable towing experience.

Hitch Pin Vulnerability To Accidental Disengagement

Hitch pins serve as a popular choice for fastening various objects together, but it is essential to consider their vulnerability to accidental disengagement. Here are some key points to understand:

- Hitch pins can be prone to accidental disengagement due to their simple design and reliance on a locking mechanism that may not always be secure.

- The pin itself can experience movement or jostling while in use, leading to unintentional release.

- Factors such as vibrations during transportation or heavy loads may contribute to the likelihood of accidental disengagement.

- In some cases, the locking mechanism or retaining clip can fail under stress, resulting in unexpected detachment.

- Accidental disengagement of a hitch pin can pose safety risks, potential damage to equipment, and inconvenience for the user.

Bolt Secure And Long-Lasting Fastening

When it comes to durability and reliability, bolts offer a secure and long-lasting fastening solution. Here are the reasons why bolts are preferred:

- Bolts provide a dependable and robust connection between components, minimizing the risk of accidental disengagement.

- The threaded design of bolts ensures a tighter grip, reducing the chances of movement or vibration-induced loosening.

- Bolts can withstand heavy loads and harsh conditions, making them suitable for various applications.

- Their solid construction and resistance to external forces make bolts highly reliable in environments prone to stress or movement.

- Unlike hitch pins, bolts are less susceptible to accidental disengagement due to their inherent locking mechanism.

While hitch pins may serve as a convenient option for certain applications, their vulnerability to accidental disengagement raises concerns regarding their durability and reliability. Bolts, on the other hand, provide a secure and long-lasting fastening solution, ensuring a dependable connection that can withstand demanding conditions.

Ideal Applications For Hitch Pins

Hitch pins are the ideal choice for securing trailers and other towing equipment. Unlike bolts, hitch pins offer easy, quick installation and removal without the need for tools or additional hardware.

Hitch pins and bolts are essential fastening tools used in various applications. In this section, we will discuss the ideal applications for hitch pins, focusing on agricultural equipment, light machinery, and trailers and towing. So, let’s dive in and explore how hitch pins play a crucial role in these specific fields:

Agricultural Equipment:

- Tractors: Hitch pins are commonly used to connect and secure implements and attachments to tractors, such as plows, harrows, and cultivators. This allows farmers to efficiently maneuver their equipment while ensuring a secure connection.

- Hay balers: Hitch pins play a vital role in attaching baling equipment to tractors, facilitating the seamless baling process. They provide the stability needed to handle the intense demands of hay and forage operations.

- Sprayers: Hitch pins are essential for securing sprayers to tractors, ensuring a steady and stable connection. This allows for efficient spraying operations in fields, boosting productivity and crop yield.

Light Machinery:

- Lawnmowers: Hitch pins are often used in lawnmowers to connect different attachments, such as trailers for hauling garden waste or fertilizer. This enables homeowners or landscapers to easily transform their lawnmowers into versatile tools for various tasks.

- Generators: Hitch pins are utilized in generators to securely fasten them to trailers or vehicles for easy transportation. This ensures that generators can be efficiently relocated to sites where power supply is needed.

- Small construction equipment: Hitch pins are commonly employed in light machinery like compact loaders and mini excavators. They facilitate the attachment of different tools, such as buckets and forks, allowing for enhanced versatility in construction and landscaping projects.

Trailers And Towing:

- Car trailers: Hitch pins are essential in towing applications, securing the hitch ball mount to the receiver hitch on vehicles. This ensures a safe and reliable connection between the towing vehicle and the trailer, preventing accidents or disconnection during transport.

- Boat trailers: Hitch pins play a crucial role in attaching the hitch coupler to the trailer’s tongue, allowing boat owners to safely transport their watercraft to various launching sites.

- Camping trailers: Hitch pins are vital for connecting the trailer hitch to the towing vehicle, whether it’s an rv or a pop-up camper. This enables adventurers to comfortably travel with all the necessary equipment, making their camping experience more enjoyable.

Hitch pins are versatile fasteners that find extensive usage in a range of applications. From agricultural machinery to light equipment and towing needs, hitch pins provide the necessary strength and stability to ensure safe and efficient operations.

Ideal Applications For Bolts

Bolts are the ideal choice for hitch pin applications due to their durability and strength. With their secure fastening capabilities, bolts provide a reliable solution for hitching trailers or securing heavy equipment. Whether it’s for towing or connecting components, bolts offer a dependable option for hitch pin needs.

Construction Projects

Bolts are commonly used in construction projects due to their strength, durability, and ability to securely hold materials together. Here are some ideal applications for bolts in construction:

- Connecting structural members: Bolts are used to join steel beams, columns, and other components in the construction of buildings, bridges, and infrastructure projects.

- Concrete formwork: Bolts are necessary for securing formwork panels, ensuring that concrete is poured and shaped correctly during construction.

- Roof and wall installation: Bolts are utilized to attach roofing and wall panels, providing a secure and weather-resistant structure.

- Fastening fixtures and fittings: Bolts are employed to secure various fixtures such as handrails, guardrails, fences, and other components to ensure safety and stability.

- Mending or reinforcing structures: Bolts are often used to repair or reinforce damaged structures, providing additional strength and support.

Heavy Machinery And Equipment

In heavy machinery and equipment, bolts play a crucial role in ensuring safety and efficient operation. Here are some examples of how bolts are used in this context:

- Equipment assembly: Bolts are essential for assembling heavy machinery and equipment, providing sturdy connections between components.

- Frame and chassis reinforcement: Bolts help reinforce the frames and chassis of machinery, ensuring structural integrity and stability during operation.

- Mounting engines and transmissions: Bolts securely fasten engines and transmissions to equipment, preventing movement and ensuring efficient power transfer.

- Fastening hydraulic and pneumatic systems: Bolts are used to connect hoses, pipes, and fittings, allowing for the safe and efficient operation of hydraulic and pneumatic systems.

- Securing attachments and accessories: Bolts are utilized to attach different accessories and components to heavy machinery and equipment, such as buckets, blades, or specialized tools.

Structural Installations

In structural installations, bolts are vital for providing strong and reliable connections between various elements. Here are some instances where bolts are commonly used:

- Steel framework construction: Bolts play a crucial role in connecting steel beams and columns, creating robust and stable structures for buildings, bridges, and other projects.

- Bridge construction: Bolts are used to join different components of bridges, including girders, piers, and abutments, ensuring structural integrity and safety.

- Industrial facilities: Bolts are employed in the construction of industrial facilities, connecting heavy structural elements to support equipment, pipes, and utility systems.

- Power transmission towers: Bolts securely fasten the various segments of power transmission towers, providing stability and continuity for electric power distribution.

- Modular construction: Bolts are used in the assembly of modular buildings and structures, ensuring that prefabricated components are securely connected and aligned.

Bolts find ideal applications in construction projects, heavy machinery and equipment, and structural installations. Their strength, durability, and versatility make them essential for connecting, securing, and reinforcing various elements in these contexts. Whether in construction sites, industrial facilities, or infrastructure projects, bolts are reliable fastening solutions that contribute to the safety and stability of structures and equipment.

Frequently Asked Questions Of Hitch Pin Vs Bolt

Can I Use A Bolt Instead Of A Hitch Pin?

No, it is not recommended to use a bolt instead of a hitch pin. A hitch pin is specifically designed to secure the connection between a hitch receiver and a trailer or hitch accessory. It is made to withstand the necessary forces and vibrations during towing.

Using a bolt in its place may not have the same strength or durability. It could potentially fail under the pressure, leading to detachment and a safety hazard. It is crucial to use the appropriate hitch pin that matches the specifications of your hitch receiver and trailer.

This will ensure a secure and reliable connection during towing.

Is A Roll Pin Stronger Than A Grade 8 Bolt?

A grade 8 bolt is stronger than a roll pin.

Is A Grade 8 Bolt Strong As A Hitch Pin?

A grade 8 bolt is strong, but it may not be as strong as a hitch pin.

What Is The Strength Of A Hitch Pin?

A hitch pin’s strength varies depending on its material and size. The strength is primarily determined by the pin’s diameter and tensile strength. Generally, hitch pins have a tensile strength ranging from 3,000 to 42,000 pounds. The larger the pin’s diameter, the stronger it is.

Hitch pins made from high-grade steel or hardened steel are stronger than those made from lower-grade materials. It is important to select a hitch pin that matches the towing capacity of your trailer or vehicle.

Conclusion

As we wrap up our exploration of hitch pins and bolts, it becomes clear that both have their own unique advantages and disadvantages. The hitch pin offers convenience and ease of use, allowing for quick attachment and detachment. On the other hand, bolts provide a stronger and more secure connection, ensuring the safety of your equipment during transport.

Ultimately, the choice between hitch pins and bolts depends on your specific needs and preferences. Consider the weight and type of load you will be towing, as well as the frequency with which you will be attaching and detaching the hitch.

Regardless of your choice, don’t forget to regularly inspect and maintain your hitch to ensure it remains in optimal condition. So, whether you opt for a hitch pin or a bolt, make an informed decision based on the requirements of your towing tasks, and enjoy a safe and worry-free journey.