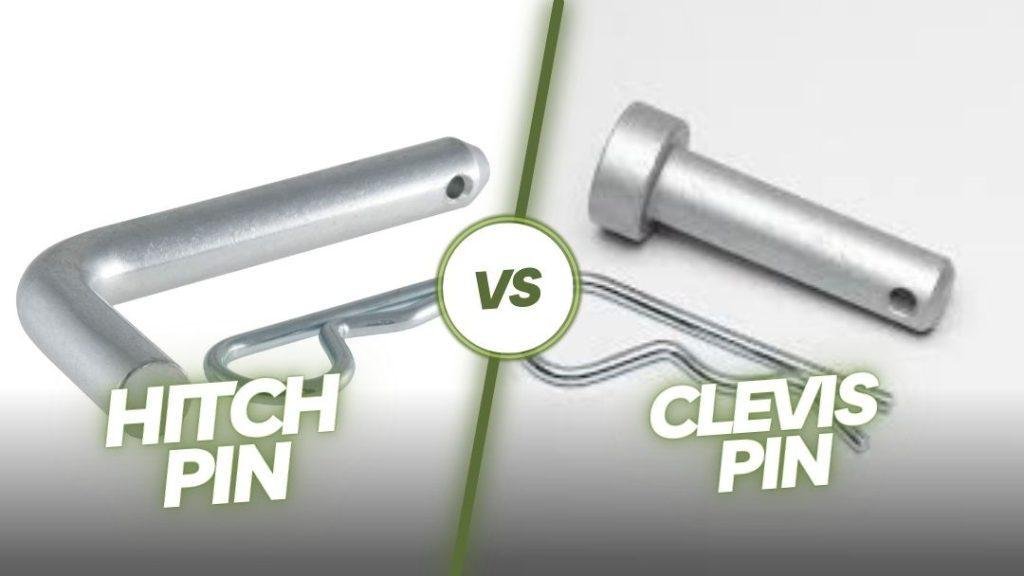

A hitch pin is a simple fastener used to secure a trailer to a hitch receiver, while a clevis pin is a type of fastener used to connect two components. Hitch pins are commonly used in towing applications, whereas clevis pins are used in a wide range of industries and applications.

The key difference between the two is their design and purpose. Hitch pins are typically designed with a handle or loop on one end for easy installation and removal, while clevis pins have a head on one end and are secured with a cotter pin or a retaining ring.

Both pins are crucial for connecting and securing components, but their specific applications and designs differentiate them.

1. What Are Hitch Pins And Clevis Pins?

Hitch pins and clevis pins are both essential fastening devices used in various applications. While hitch pins feature a simple design with a removable cotter pin, clevis pins have a more versatile design with a head and hole for attaching other components.

Choosing the right option depends on your specific needs and requirements.

Hitch pin vs clevis pin: what are hitch pins and clevis pins?

Definition And Purpose Of Hitch Pins:

- Hitch pins are simple, yet essential, devices used to secure trailers or implements to a tow vehicle. They are commonly employed in agricultural, construction, and recreational settings.

- These steel pins feature a horizontal handle or lever on one end and a bendable loop, known as a cotter pin, on the other end. The handle prevents the pin from sliding out, while the cotter pin ensures it stays in place.

- Hitch pins are primarily used to secure towing hitches, lunettes, and tractors to trailers, providing stability during transportation. They play a crucial role in preventing accidents and ensuring safe towing operations.

Definition And Purpose Of Clevis Pins:

- Clevis pins are another type of fastening device commonly used in various applications, such as mechanical, agricultural, and industrial settings.

- Consisting of a cylindrical body with holes at both ends, clevis pins have a versatile design that allows them to be used with various attachments, including clevises, yokes, and other connecting tools.

- These pins secure the components together, forming a stable connection that can support tension and shear forces, making them ideal for heavy-duty applications.

Different Designs And Variations Of Hitch Pins And Clevis Pins:

Hitch pins:

- Standard hitch pins: The most common type, featuring a straight, solid pin body with a handle on one end and a cotter pin on the other.

- Quick-release hitch pins: These pins utilize a spring-loaded mechanism that allows for easy installation and removal without the need for a separate cotter pin.

- Locking hitch pins: Designed with an additional locking mechanism, these pins provide an extra layer of security, preventing accidental disengagement during transportation.

- Safety hitch pins: Similar to standard hitch pins, but with a swiveling handle that can be easily rotated into a locked position, ensuring enhanced safety and peace of mind.

Clevis pins:

- Standard clevis pins: These pins have a solid cylindrical body with holes at both ends, allowing for easy attachment of clevises or other implements.

- Cotterless clevis pins: With a self-locking feature, these pins eliminate the need for cotter pins by utilizing a spring-loaded ball and detent system.

- Threaded clevis pins: These pins have threaded bodies and are commonly used when a secure and adjustable connection is required.

- Quick-release clevis pins: Featuring a push-button release mechanism, these pins offer convenient installation and removal for applications that require frequent component changes.

Understanding the definitions and variations of hitch pins and clevis pins is crucial when selecting the right fastening device for your specific needs. Whether you require a secure connection for towing or a versatile attachment for heavy-duty components, choosing the appropriate pin type will ensure safety and efficiency in your operations.

2. Pros And Cons Of Hitch Pins

Hitch pins and clevis pins both have pros and cons. Hitch pins offer easy installation and removal, but clevis pins provide greater strength and security. Consider your specific needs and preferences before choosing between the two.

Pros And Cons Of Hitch Pins

Hitch pins are commonly used in various applications as fasteners. They provide convenience and reliability, but like any other tool or technology, they also come with their own advantages and disadvantages. In this section, we will explore the benefits and limitations of hitch pins, as well as the common applications where they excel.

Advantages Of Using Hitch Pins:

- Versatility: Hitch pins can be used in a wide range of applications, making them a versatile fastening option. Whether it’s securing equipment, attaching accessories, or connecting components, hitch pins offer flexibility in usage.

- Easy to install: One of the key advantages of hitch pins is their simplicity in installation. It’s a quick and hassle-free process, requiring minimal effort and no additional tools.

- Quick release: Hitch pins feature a simple mechanism that allows for a quick release when needed. This is particularly beneficial in situations where frequent attachment and detachment are required.

- Secure hold: When properly engaged, hitch pins provide a secure and reliable hold. They are designed to prevent accidental dislodgement, ensuring the safety of the connected components.

Disadvantages And Limitations Of Hitch Pins:

- Limited load capacity: Hitch pins have a specific load capacity, and they may not be suitable for heavy-duty applications or those involving significant weight-bearing requirements. It’s important to carefully consider the maximum weight that can be safely supported by a hitch pin before use.

- Vulnerability to vibrations: Due to their design, hitch pins can be susceptible to vibrations, especially in high-impact applications. This can potentially cause the pin to loosen over time, leading to reduced stability and compromised performance.

- Risk of loss or misplacement: Hitch pins are relatively small and can be easily misplaced if not properly secured or stored. This can lead to inconveniences and delays, especially when working in situations where time is crucial.

Common Applications Where Hitch Pins Excel:

- Agriculture and farming: Hitch pins are commonly used in agricultural equipment to connect various components, such as blades, tillers, and attachments. Their ease of installation and quick release functionality make them ideal for farming operations.

- Trailer coupling: Hitch pins are widely used in the hitching process of trailers to vehicles. They provide a secure and durable connection, ensuring safe towing on the road.

- Mechanical and automotive applications: Hitch pins find their utility in mechanical and automotive settings, particularly for attaching and securing parts, linkage systems, and accessories. Their versatility and ease of use make them valuable in these applications.

- Recreational equipment: Hitch pins are prevalent in recreational activities, such as outdoor sports and camping. They are used to connect towable equipment like bike trailers, trailers for water sports, and more.

While hitch pins offer versatility, easy installation, and quick release capabilities, they do have limitations in terms of load capacity, vulnerability to vibrations, and the risk of loss or misplacement. They excel in various applications, including agriculture, trailer coupling, mechanical and automotive settings, as well as recreational equipment.

It’s essential to consider the specific requirements and limitations of hitch pins before incorporating them into any project or application.

3. Pros And Cons Of Clevis Pins

Clevis pins and hitch pins each have their pros and cons. Clevis pins offer better load distribution and flexibility, while hitch pins are more secure and less prone to accidental release. Choose based on your specific needs.

Clevis pins are versatile fasteners that offer several advantages in various applications. However, they also have certain limitations that need to be considered. Let’s explore the pros and cons of using clevis pins:

Advantages Of Using Clevis Pins:

- Easy to install: Clevis pins are simple to insert and remove, making them convenient for assembly and disassembly tasks.

- Secure fastening: These pins provide a reliable and sturdy connection, ensuring that attached components remain firmly in place.

- Adjustable positioning: Clevis pins allow for adjustable positioning of attached parts, offering flexibility and the ability to fine-tune their alignment.

- Cost-effective solution: Clevis pins are typically affordable and readily available, making them a cost-efficient choice for many industrial and mechanical applications.

- Wide variety of sizes and materials: Clevis pins come in various sizes and can be manufactured from different materials to suit specific requirements.

Disadvantages And Limitations Of Clevis Pins:

- Limited load capacity: Clevis pins may have a lower load capacity compared to other fasteners such as bolts or rivets. It’s crucial to consider the maximum load requirements before using clevis pins.

- Limited rotational resistance: In some applications, clevis pins may not provide sufficient resistance to rotational forces. Additional measures may be needed to prevent unwanted rotation.

- Potential for misalignment: Due to their adjustable nature, clevis pins can be susceptible to misalignment if not properly secured. Regular inspections and maintenance are necessary to ensure proper alignment and prevent failures.

- Vulnerable to corrosion: Depending on the material used, clevis pins can be susceptible to corrosion over time, especially in harsh or corrosive environments. Using appropriate materials or protective coatings can mitigate this issue.

- Additional hardware may be required: In certain applications, additional hardware such as hairpin cotter pins or retaining rings may be needed to ensure the clevis pin stays securely in place.

Common Applications Where Clevis Pins Excel:

- Automotive industry: Clevis pins are commonly used in automotive applications for connecting various components such as suspension systems, brake systems, and throttle linkages.

- Agriculture and farming equipment: Clevis pins find extensive use in agricultural machinery, attaching implements and components such as plows, harrows, and cultivators.

- Construction and infrastructure: Clevis pins are utilized in construction and infrastructure projects, securing components of scaffolding, formwork, and heavy machinery.

- Industrial machinery: Clevis pins are integral in the assembly of industrial machinery, allowing for easy adjustment and attachment of parts in manufacturing processes.

Clevis pins offer advantages such as easy installation, secure fastening, adjustable positioning, cost-effectiveness, and a variety of sizes and materials. However, they have limitations including limited load capacity, rotational resistance, potential misalignment, vulnerability to corrosion, and the potential need for additional hardware.

Clevis pins excel in applications within the automotive, agriculture, construction, and industrial machinery sectors.

4. Hitch Pins Vs Clevis Pins: Strength And Durability

Hitch pins and clevis pins each offer unique strengths and durability. Understanding the differences between these fastening options is crucial for making the right choice for your application.

Comparison Of Strength And Durability Between Hitch Pins And Clevis Pins

Hitch pins and clevis pins are both commonly used for attaching implements to tractors or other machinery. When selecting between the two options, it is crucial to consider their strength and durability. Here, we will compare hitch pins and clevis pins in terms of these factors.

Factors To Consider When Choosing Between The Two Based On Strength Requirements:

- Material composition:

- Hitch pins are typically made of hardened steel, offering excellent strength and toughness.

- Clevis pins are also made of steel but may not be as strong as hitch pins due to their thinner construction.

- Load-bearing capacity:

- Hitch pins are designed to handle heavy loads and provide reliable support for attachments, thanks to their sturdy build.

- Clevis pins may have a lower load-bearing capacity compared to hitch pins, making them more suitable for lighter applications.

- Pin diameter and shear strength:

- Hitch pins often come in larger diameters, contributing to their impressive resistance against shearing forces.

- Clevis pins, on the other hand, may have smaller diameters and might not possess the same level of shear strength as hitch pins.

Factors To Consider When Choosing Between The Two Based On Durability Requirements:

- Corrosion resistance:

- Hitch pins are commonly coated with corrosion-resistant finishes, such as zinc or powder coating, enhancing their durability and longevity.

- Clevis pins may lack such coatings, making them more prone to rust and corrosion over time.

- Wear resistance:

- Hitch pins are often built to withstand rugged conditions and exhibit excellent wear resistance, ensuring long-lasting performance.

- Clevis pins, especially those without additional treatments, may not offer the same level of wear resistance as hitch pins.

- Overall lifespan:

- Hitch pins, given their robust construction and protective coatings, generally have a longer lifespan compared to clevis pins.

- Clevis pins might be more suitable for temporary or lighter-duty applications where prolonged durability is not a significant concern.

When choosing between hitch pins and clevis pins, it is crucial to assess your specific strength and durability requirements. Consider factors such as load-bearing capacity, pin diameter, corrosion resistance, wear resistance, and overall lifespan. By carefully evaluating these aspects, you can make an informed decision on which pin type best suits your needs.

5. Hitch Pins Vs Clevis Pins: Ease Of Use And Installation

Hitch pins and clevis pins both offer easy installation and use, but differ in their design and application. Hitch pins have a simpler design with a single pin that slides through the hitch receiver, while clevis pins are secured with a cotter pin or clip and used in applications where higher strength is required.

Choose the right pin based on your specific needs.

Comparison Of Ease Of Use And Installation Between Hitch Pins And Clevis Pins

Hitch pins and clevis pins are both commonly used in various applications, but they differ in terms of ease of use and installation. Let’s dive into the details to understand the advantages and considerations for each type of pin.

Hitch Pins:

- Straightforward installation: Hitch pins are simple to install, requiring minimal effort. They come in various sizes and are placed through the designated holes in the hitch receiver and the attachment, such as a trailer tongue or hitch-mounted accessory.

- Quick and convenient: With their basic design, hitch pins can be easily inserted or removed whenever necessary, making it effortless to connect and disconnect trailers or other hitch-mounted equipment.

- Secure locking mechanism: Many hitch pins come with built-in locking mechanisms, such as a cotter pin or a spring clip, which add an extra layer of security and prevent accidental disengagement during transportation.

- Versatility: Hitch pins can be used with a wide range of hitch configurations, including ball mounts, receiver hitches, and pintle hooks, making them adaptable for various towing and hauling needs.

Clevis Pins:

- Adjustable and adaptable: Clevis pins offer the advantage of adjustability due to their threaded end, which allows for flexible positioning and customization based on different applications and user requirements.

- High load-bearing capacity: Clevis pins are favored for heavy-duty applications due to their ability to handle significant loads with stability and reliability. They provide a strong connection between the components they secure.

- Secure fastening: Clevis pins commonly come with a cotter pin or a snap ring that secures the pin in place, providing added safety by preventing accidental dislodgment or rotation.

- Ideal for angular movement: The adjustable nature of clevis pins, combined with their ability to allow angular movement, makes them suitable for use in applications where pivoting or rotating connections are required.

Considering their distinct characteristics, the choice between hitch pins and clevis pins depends on the specific application and user requirements. Hitch pins are preferred for their simplicity, ease of use, and universal compatibility, whereas clevis pins excel in heavy-duty applications, offering adjustability and secure fastening.

Whether it’s towing a trailer or securing heavy machinery, understanding the ease of use and installation differences between hitch pins and clevis pins helps determine the optimal pin choice for each scenario.

6. Hitch Pins Vs Clevis Pins: Versatility And Adaptability

Hitch pins and clevis pins offer versatility and adaptability in various applications. These pins are essential for securing and adjusting attachments, providing a reliable and efficient solution for fastening tasks. With their unique designs and easy installation, both hitch pins and clevis pins ensure a secure connection, making them indispensable tools in any industrial or agricultural setting.

H3: comparison of versatility and adaptability between hitch pins and clevis pins

When it comes to choosing between hitch pins and clevis pins, it’s important to consider their versatility and adaptability. Both types of pins have their own unique features and applications, making them suitable for different scenarios. Let’s take a closer look at how these two options compare in terms of versatility and adaptability:

Hitch Pins:

- Hitch pins are commonly used in towing and hauling applications. Their primary function is to secure a hitch or trailer to a vehicle, providing a reliable connection.

- They are available in various sizes and designs, allowing for versatility in different types of towing setups.

- Hitch pins typically have a simple design, consisting of a pin with a handle or a locking mechanism on one end and a clip or cotter pin on the other end.

- Their straightforward design and ease of use make hitch pins suitable for quick attachments and releases.

- Hitch pins can be used with receivers, ball mounts, drawbars, and other hitch accessories, providing a secure connection between the vehicle and the load.

- These pins have a broad range of applications, including towing trailers, attaching agricultural implements, and securing equipment during transportation.

Clevis Pins:

- Clevis pins are known for their versatility and adaptability in various mechanical and industrial applications.

- They consist of a cylindrical pin with one or more holes, allowing for different attachment points and configurations.

- Clevis pins are commonly used in conjunction with clevises, yokes, and other components to create adjustable connections.

- The holes in clevis pins offer multiple options for positioning and adjusting the attachment, providing flexibility in different setups.

- Clevis pins can be secured with cotters, clips, or retaining rings, ensuring a reliable connection.

- They find applications in industries such as agriculture, construction, automotive, and machinery, where adjustable connections are required.

In certain scenarios, one type of pin may be more suitable than the other:

- When a secure and quick connection is needed, hitch pins are the go-to option due to their simple design and easy attachment.

- If there is a requirement for adjustability and flexibility in the connection setup, clevis pins with their multiple holes become the preferred choice.

- Clevis pins are often used in applications where precise alignment or angle adjustments are necessary.

- In heavy-duty applications or situations where additional load-bearing capacity is needed, clevis pins are typically more suitable due to their robust design.

Both hitch pins and clevis pins have their own strengths when it comes to versatility and adaptability. The choice between the two depends on the specific requirements of the application, whether it be towing, hauling, or adjustable connections. Understanding the advantages and applications of each pin type allows for informed decision-making, ensuring a secure and efficient connection in various scenarios.

7. Hitch Pins Vs Clevis Pins: Safety And Security

Hitch pins and clevis pins play vital roles in ensuring safety and security in various applications. While hitch pins are commonly used for towing and connecting equipment, clevis pins are preferred for higher load capacities and added stability. Choosing between hitch pins and clevis pins requires careful consideration of the specific needs and requirements of the task at hand.

Hitch pins and clevis pins are two different types of fasteners commonly used in various applications. When it comes to safety and security, it is crucial to understand the features and considerations of both hitch pins and clevis pins to prevent accidents and ensure proper attachment.

In this section, we will compare the safety and security aspects of these two types of pins.

Comparison Of Safety And Security Features Of Hitch Pins And Clevis Pins:

There are several factors to consider when evaluating the safety and security features of hitch pins and clevis pins:

- Attachment mechanism: Hitch pins typically have a simple snap-lock or swivel-lock mechanism, making them quick and easy to install and remove. Clevis pins, on the other hand, usually require additional hardware such as a cotter pin or r-clip to secure the connection.

- Strength and load capacity: Both hitch pins and clevis pins are designed to handle specific load capacities. It is essential to choose a pin that meets the requirements of your application to ensure optimal safety and prevent failures.

- Visibility and accessibility: Hitch pins are often more visible due to a larger head or a bright-colored handle, making them easier to locate and inspect. Clevis pins may be less visible, especially when covered by other components or hidden in machinery.

- Retention mechanisms: Clevis pins with cotter pins or r-clips provide an additional layer of security by preventing the pin from coming loose accidentally due to vibrations or movement. Hitch pins may not have retention mechanisms unless additional accessories like hairpin cotters are used.

- Durability and corrosion resistance: Both types of pins are typically made from strong and durable materials such as stainless steel or hardened steel alloys. However, it is essential to consider the environmental conditions and choose a pin with suitable corrosion resistance to ensure long-term safety and reliability.

- Ease of inspection: Regular visual inspections are crucial for maintaining the safety of hitch pins and clevis pins. Hitch pins allow for a quick visual check of the locking mechanism, while clevis pins require inspecting the cotter pin or r-clip as well.

Considering these factors when selecting and using hitch pins or clevis pins is vital to promote safety, prevent accidents, and ensure secure attachments. By choosing the appropriate pin for your application and following proper installation practices, you can enhance the safety and security of your equipment or machinery.

8. Hitch Pins Vs Clevis Pins: Cost And Availability

Hitch pins and clevis pins differ in terms of cost and availability. While hitch pins tend to be more affordable and widely accessible, clevis pins may be harder to find and come at a higher price point.

Comparison Of Cost And Availability Of Hitch Pins And Clevis Pins

Hitch pins and clevis pins are important components for connecting various equipment in different applications. When it comes to choosing between these two options, one of the key considerations is the cost and availability. Let’s explore the factors that influence the pricing and availability of hitch pins and clevis pins in the market:

Factors That Influence Pricing And Availability In The Market:

- Material used:

- Hitch pins and clevis pins are available in various materials such as steel, stainless steel, and brass. The choice of material can impact the pricing, with stainless steel generally being more expensive than regular steel. Availability may also depend on the demand for specific materials.

- Size and dimensions:

- Hitch pins and clevis pins come in different sizes and dimensions to accommodate various applications. Larger pins or pins with unique dimensions may be more expensive and less readily available due to a lower demand compared to standard sizes.

- Quantity:

- Purchasing in bulk can often lead to cost savings as suppliers may offer discounts for larger orders. Availability of hitch pins and clevis pins in specific quantities can vary depending on the stock levels maintained by suppliers.

- Brand and quality:

- Hitch pins and clevis pins from well-known brands or those with a reputation for higher quality may command a premium price. Additionally, availability of specific brands may vary depending on the region and the distribution network.

- Market demand:

- The overall demand for hitch pins and clevis pins in the market can impact both pricing and availability. Higher demand may lead to increased prices and potential scarcity of certain types or sizes of pins.

- Supplier relationships:

- Establishing strong relationships with reliable suppliers can have an influence on both the cost and availability of hitch pins and clevis pins. Preferred suppliers may offer competitive prices and prioritize supply to maintain customer satisfaction.

- Market competition:

- Competition among various manufacturers and suppliers can affect the pricing of hitch pins and clevis pins. A more competitive market may result in lower prices and better availability due to the wide range of options available.

Considering these factors, it’s important to research and compare prices from multiple suppliers to ensure getting the best value for money while also considering the availability of the required hitch pins and clevis pins for specific applications.

9. Conclusion: Choosing The Right Pin For Your Needs

Choosing between a hitch pin and a clevis pin can be a tough decision. Consider your needs and the specific application to make the right choice for your situation.

Summary Of The Key Points Discussed In The Article:

- Hitch pins and clevis pins are both commonly used in various applications to secure components together.

- Hitch pins are designed with a loop at one end and a detachable pin at the other, making them easy to install and remove. They are often used to secure trailers to hitch receivers and implements to tractors.

- Clevis pins consist of a cylindrical pin with a hole drilled through it and a separate fastening device. They are typically used for applications requiring a secure connection that can handle heavier loads.

- Both types of pins come in different sizes and materials to accommodate various needs and preferences.

- Consider the intended use, load capacity, diameter, length, and attachment method when selecting between hitch pins and clevis pins.

- If you need a quick and easy attachment and detachment option, hitch pins are the way to go. On the other hand, clevis pins provide a more reliable and secure connection for heavy-duty applications.

- Hitch pins are commonly used for towing purposes and in applications where convenience and speed of installation are essential.

- Clevis pins are ideal for applications that require a robust and solid connection, such as securing equipment or joining structural components.

- It is crucial to determine the load capacity and select the appropriate pin size to ensure safety and prevent failures.

- Before making a decision, carefully evaluate your specific needs, equipment requirements, load capacity, and the level of security you desire.

Factors To Consider When Making A Decision Between Hitch Pins And Clevis Pins:

- Load capacity: Determine the maximum load that the pin will need to handle and select a pin that meets or exceeds this requirement. Consider the length and diameter that can withstand the anticipated loads.

- Application: Evaluate the specific application or equipment you are working with. Consider factors such as the level of force, vibration, and movement involved.

- Convenience: If you need a quick and easy attachment and removal option, hitch pins are a suitable choice. They offer convenience and are often used in situations where frequent connection changes are necessary.

- Security: For applications requiring a more secure and reliable connection, clevis pins offer superior strength. They are designed to handle heavy-duty loads and provide a sturdy connection.

- Durability: Consider the material and finish of the pins. The right material choice ensures longevity and resistance to rust or corrosion, improving the overall lifespan of the pins.

- Size and compatibility: Determine the appropriate size and compatibility for your specific application. Measure the diameter of the required hole, and select a pin that fits snugly to prevent any unwanted movement or play.

Recommendations Based On Different Use Cases And Requirements:

- For general towing purposes or applications that require frequent attachment and detachment, hitch pins are the most suitable choice. They provide a convenient and efficient solution, allowing for quick and hassle-free connections.

- If you are dealing with heavy equipment or high-load applications, clevis pins are recommended. Their design ensures a more secure connection and can handle the increased weight and force involved.

- When safety is a top priority, especially in critical applications, opt for clevis pins. They provide a more reliable and solid connection, reducing the risk of failure or accidents.

- Consider the environment and conditions in which the pins will be used. Stainless steel or zinc-plated pins are ideal for outdoor applications as they offer enhanced corrosion resistance.

- Take into account the overall cost and budget. Clevis pins tend to be more expensive than hitch pins due to their heavy-duty construction and added security features. Evaluate your requirements and budgetary constraints before making a decision.

Remember, the choice between hitch pins and clevis pins ultimately depends on your specific needs, load requirements, and desired level of security. Carefully consider the factors discussed here to ensure you select the right pin for the job.

Frequently Asked Questions On Hitch Pin Vs Clevis Pin

What Is The Difference Between A Hitch Pin And A Linch Pin?

A hitch pin and a linch pin are two types of fasteners often used in the transportation industry. They both serve the purpose of securing a trailer or other equipment to a hitch receiver. However, there is a key difference between the two.

A hitch pin typically features a latch or locking mechanism that prevents it from accidentally coming out of the hitch receiver. This provides an extra level of security during transportation. On the other hand, a linch pin does not have a latch or locking mechanism.

It relies on the tension created by the pin’s shape to hold it in place. In summary, a hitch pin offers more security due to its locking mechanism, while a linch pin is simpler in design and requires careful installation to ensure it remains in place.

What Is Another Name For A Hitch Pin?

Another name for a hitch pin is a trailer pin. It is a commonly used term for the pin that secures a trailer hitch to a towing vehicle. The hitch pin is an essential component that attaches the trailer to the receiver hitch on the vehicle, ensuring a secure and safe connection.

This pin prevents the trailer from accidentally becoming detached from the towing vehicle during transportation. The trailer pin is typically made of sturdy materials like steel and has a simple design with a straight shaft and a crossbar at one end.

It is inserted into the hitch receiver and secured with a clip or lock to keep it in place. Using a proper hitch pin is crucial for a successful and trouble-free towing experience.

What Is A Hitch Pin Used For?

A hitch pin is used to securely connect a trailer or towing device to the hitch receiver of a vehicle. It acts as a safety mechanism, ensuring that the trailer remains properly attached during transportation. The hitch pin is inserted through the hitch receiver and the corresponding hole in the trailer hitch or towing device, locking them together.

This prevents the trailer from becoming detached and causing accidents or damage. Hitch pins are typically made of sturdy materials such as steel, ensuring strength and durability. They come in various sizes to accommodate different types of hitch receivers and trailers.

It is important to choose a hitch pin that is compatible with your hitch receiver and properly secure it to ensure safe towing.

What Is The Difference Between A Clevis Pin And A Cotter Pin?

A clevis pin and a cotter pin are two different types of fasteners used in mechanical applications. A clevis pin is a cylindrical pin with a hole at one end and a head at the other, designed to secure components that require rotational movement.

On the other hand, a cotter pin is a flat, tapered pin that is inserted through a hole and bent to secure various components, preventing them from loosening or rotating. The main difference between the two is their shape and method of securing.

Clevis pins are used in conjunction with a clevis, which has a hole where the pin is inserted, while cotter pins are inserted into a hole and secured by bending the ends. Clevis pins are often used to connect rods or cables to a moving part, while cotter pins are commonly used to secure bolts, nuts, or other fasteners.

Knowing the difference between these two pins can help ensure proper usage and secure fastening in various mechanical applications.

Conclusion

The comparison between hitch pins and clevis pins has highlighted the unique features and applications of each. Hitch pins provide a secure and efficient way to connect and detach trailer hitch equipment, making them ideal for towing applications. On the other hand, clevis pins offer versatility and flexibility for various mechanical and industrial uses, thanks to their adjustable and detachable nature.

Understanding the differences between these two types of pins is essential in choosing the right option for your specific needs. Consider factors such as load capacity, security, ease of use, and compatibility with your equipment. Remember, whether you opt for a hitch pin or a clevis pin, always prioritize safety and ensure proper installation.

Consult the manufacturer’s guidelines and seek professional advice when needed. Keep these insights in mind and make an informed decision when it comes to selecting hitch pins or clevis pins for your projects. Happy pinning!