An anchor shackle is a metal device used to connect chains or ropes in various industries. It provides a secure connection point for lifting, towing, or securing heavy loads.

Anchor shackles are designed to withstand high loads and come in various sizes and materials to suit different applications. They are commonly used in marine, construction, and mining industries, as well as in agriculture and transportation. With their durable and reliable construction, anchor shackles play a crucial role in ensuring the safety and stability of heavy equipment and operations.

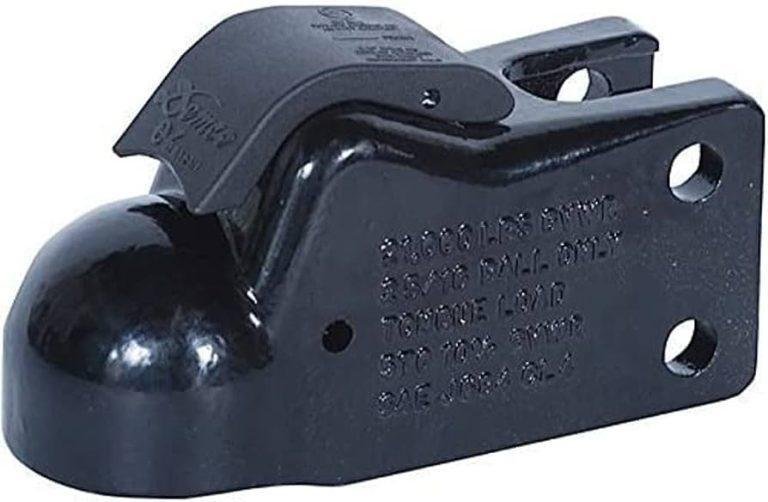

Credit: www.amazon.com

Understanding The Functionality Of Anchor Shackles

Anchor shackles are essential components used in rigging and lifting operations. They provide a strong and reliable connection point for securing loads. These shackles are designed to withstand heavy loads and ensure safety during towing, hoisting, and other related activities.

Differentiating Anchor Shackles From Other Rigging Tools:

- Anchor shackles are a type of rigging tool used for connecting and securing various materials in industries like construction, maritime, and manufacturing. Here’s how they differ from other rigging tools:

- Anchor shackles are designed with a u-shaped body and a removable pin or bolt, allowing for easier attachment and detachment of loads. Unlike other rigging tools, anchor shackles offer a more secure and reliable connection.

- While other rigging tools like snap shackles or d-rings may share similar functionalities, anchor shackles excel in heavy-duty applications thanks to their superior strength and load-bearing capacity.

- Unlike wire rope clips or turnbuckles, anchor shackles provide a quick and convenient solution for connecting different objects or loads, making them a preferred choice in various industries.

Understanding The Functionality Of Anchor Shackles In Various Industries:

- Anchor shackles find extensive use across multiple industries due to their versatility and strength. Here are some notable applications:

- Construction industry:

- Used for securing and connecting heavy construction materials such as steel beams, scaffolding, or concrete forms.

- Ideal for lifting and suspending heavy loads with the help of cranes or hoists.

- Facilitates the assembly of temporary structures such as tents or stages.

- Maritime industry:

- Crucial for mooring operations, securing ropes or chains to anchors, and docking ships.

- Used in shipbuilding for attaching cable, rigging, or equipment.

- Essential in offshore oil and gas extraction for strengthening connections and withstanding harsh marine conditions.

- Manufacturing industry:

- Employed in conveyor systems for attaching and controlling material movement.

- Used in manufacturing equipment such as presses, hoists, or lifting machinery.

- Essential for securing heavy industrial equipment during transportation or assembly.

- Entertainment industry:

- Essential for rigging stage equipment, lighting, and sound systems.

- Used in the construction of film sets or event structures.

- Facilitates aerial rigging for acrobatics, stunts, or aerial performances.

Exploring The Different Types Of Anchor Shackles:

- Anchor shackles come in various types, each suited for specific applications. Let’s take a closer look:

- Screw pin anchor shackles:

- Feature a threaded pin that can be easily screwed in and out for quick attachment or detachment.

- Well-suited for non-permanent connections or applications that require frequent changes.

- Provides a secure and reliable connection during light to medium-duty operations.

- Bolt anchor shackles:

- Utilize a bolt and nut mechanism for secure attachment, ensuring increased strength and load-bearing capacity.

- Ideal for heavy-duty applications that require maximum strength and stability.

- Often used in industries such as construction, mining, or engineering.

- Safety anchor shackles:

- Incorporate a safety pin or cotter pin alongside the pin or bolt for additional security.

- Prevent accidental loosening or detachment of loads, enhancing safety in critical operations.

- Widely used when working with elevated loads or in situations where a failure could have severe consequences.

Remember, anchor shackles are essential rigging tools that provide a reliable and versatile solution for connecting and securing objects in various industries. Understanding the different types and their applications ensures the appropriate use of anchor shackles for specific needs.

The Key Components Of An Anchor Shackle

An anchor shackle is composed of several key components, including a pin, a body, and a closure mechanism. These components work together to provide a secure and reliable connection point for heavy-duty applications.

Anchor shackles are crucial components in various industries, including maritime, construction, and rigging. They play a vital role in connecting and securing heavy loads. Understanding the key components of an anchor shackle is essential for selecting the right one for your specific application.

In this section, we will delve into two important aspects: pin and body materials, and the importance of load capacity.

Pin And Body Materials Used In Anchor Shackles:

Anchor shackles are typically composed of two main parts: the pin and the body. These components are available in different materials, each offering unique properties and benefits. Here are the common materials used for anchor shackle pins and bodies:

- Pin materials:

- Carbon steel: This is the most commonly used material for shackle pins, as it provides excellent strength and durability.

- Alloy steel: These pins are made from steel alloyed with other elements such as chromium, molybdenum, or vanadium to enhance their strength and toughness.

- Stainless steel: Shackles with stainless steel pins are highly resistant to corrosion and suitable for applications in corrosive environments.

- Body materials:

- Carbon steel: Similar to pin materials, carbon steel is often used for shackle bodies due to its strength and durability. It is suitable for general-purpose applications.

- Alloy steel: Shackles with alloy steel bodies offer increased strength and durability, making them ideal for heavy-duty applications.

- Stainless steel: Shackle bodies made of stainless steel provide excellent resistance to corrosion, making them suitable for marine and other high-corrosion environments.

Understanding the material options for anchor shackle pins and bodies is critical for choosing the right shackle that can withstand the specific demands of your application.

Understanding The Importance Of Load Capacity:

When it comes to anchor shackles, load capacity is a critical factor that should not be overlooked. The load capacity refers to the maximum weight that an anchor shackle can safely support without experiencing failure. Here’s why load capacity is crucial:

- Safety: Using an anchor shackle with a load capacity lower than the actual load can jeopardize the safety of workers and equipment. It increases the risk of accidents and equipment failure, potentially leading to injuries or property damage.

- Durability: Overloading anchor shackles can cause excessive stress on the components, leading to premature wear and failure. Using shackles with the appropriate load capacity ensures their longevity and optimal performance.

Key Factors To Consider When Selecting An Anchor Shackle:

When selecting an anchor shackle for your specific application, several key factors should be taken into account to ensure its suitability. Consider the following aspects:

- Working load limit (wll): The wll indicates the maximum load that a shackle can safely handle under normal working conditions. It is crucial to choose a shackle with a wll that exceeds your intended load to ensure its safety and reliability.

- Shackle type: Different shackle types, such as bow shackles or dee shackles, have varying design features that make them suitable for specific applications. Evaluate the type of shackle that best fits your needs based on factors like load angle, attachment method, and intended use.

- Shackle size: Shackle sizes are determined by their diameter and can significantly impact their load capacity. Ensure that you choose the appropriate size that matches your load requirements while considering other factors like working space and equipment compatibility.

- Environmental conditions: Consider the environmental conditions to which the shackle will be exposed. Factors such as temperature, moisture, and corrosive substances can affect the shackle’s material selection, ensuring it can withstand the environment’s demands.

By carefully considering these key factors, you can select the right anchor shackle that meets your specific requirements while ensuring safety and optimal performance.

Remember, choosing the appropriate anchor shackle is crucial to ensure the safety and efficiency of your operations. Consider the pin and body materials, understand load capacity, and take into account key factors when making your selection. By doing so, you can confidently secure heavy loads and accomplish your tasks with ease.

Proper Usage And Safety Guidelines For Anchor Shackles

An anchor shackle is a crucial component for securing heavy loads. Follow proper usage and safety guidelines to ensure its effectiveness and prevent accidents.

Ensuring Proper Rigging Techniques With Anchor Shackles:

- Always choose the correct type and size of anchor shackle based on the load requirements.

- Avoid using damaged or worn-out shackles as it can compromise the safety of the rigging.

- Ensure that the shackle’s pin is properly secured and tightened to prevent accidental disengagement.

- When connecting the shackle to the anchor point, make sure the pin is aligned with the holes and that it fits snugly.

- Maintain a straight alignment between the shackle and the intended direction of force to prevent side-loading.

- Double-check the load weight and the working load limit (wll) to ensure that the shackle can handle the required capacity.

- Use appropriate rigging techniques and configurations to distribute the load evenly and prevent potential stress points on the shackle.

Understanding The Importance Of Regular Inspections And Maintenance:

- Conduct frequent visual inspections of the anchor shackles for signs of wear, distortion, or damage.

- Inspect the pin and the pin holes for any indications of deformation or excessive wear.

- Regularly lubricate the shackle’s pin to prevent corrosion and ensure smooth operation.

- If any defects or abnormalities are detected during inspections, immediately remove and replace the shackle.

- Implement a maintenance schedule that includes cleaning, lubricating, and periodic load testing of the anchor shackles.

- Keep detailed records of inspections and maintenance activities to track the shackle’s performance over time.

Safety Precautions To Follow When Using Anchor Shackles In Different Applications:

- When lifting or rigging heavy loads, ensure that the shackles are properly rated for the task.

- Avoid using anchor shackles for purposes other than their intended use to prevent accidents or equipment failure.

- Always wear appropriate personal protective equipment (ppe) when handling or working near anchor shackles.

- Do not exceed the working load limit (wll) specified by the manufacturer to prevent overloading.

- Be cautious of potential pinch points when using shackles in rigging configurations.

- Inspect the shackles and other rigging components regularly for signs of wear or damage.

- Follow industry safety standards and guidelines when using anchor shackles in specific applications, such as marine, construction, or industrial settings.

Remember, proper usage and adherence to safety guidelines are crucial for the safe and effective use of anchor shackles. Regular inspections, maintenance, and the implementation of appropriate rigging techniques will help ensure the durability and reliability of these essential rigging components.

Stay vigilant and prioritize safety in all anchor shackle applications.

Benefits Of Using Anchor Shackles For Rigging

Anchor shackles are essential for rigging applications, providing numerous benefits. They offer strong and secure connections, easy installation and removal, and the ability to bear heavy loads. Whether for industrial or recreational use, anchor shackles are a reliable choice for effective rigging.

Enhanced Strength And Durability For Heavy-Duty Lifting:

Anchor shackles are essential rigging components that offer enhanced strength and durability for heavy-duty lifting operations. These robust shackles are designed to withstand high loads and provide reliable support, making them suitable for a wide range of challenging applications across various industries.

Here are some key benefits of using anchor shackles for rigging:

- Increased load capacity: Anchor shackles are engineered to handle heavy loads, making them suitable for lifting and securing heavy objects. Their sturdy construction and high-tensile strength enable them to withstand significant weight without compromising the safety of the lifting operation.

- Resilience against extreme conditions: Anchor shackles are built to endure harsh environments, including extreme temperatures, corrosive substances, and abrasive conditions. Their resilience ensures that they remain functional and perform optimally even in challenging working conditions.

- Long-lasting durability: Anchor shackles are typically constructed from high-grade materials such as alloy steel, ensuring exceptional durability and longevity. Their robust design minimizes the risk of deformation or breakage, providing a reliable and secure connection during rigging operations.

- Safety assurance: The strength and durability of anchor shackles contribute to the overall safety of rigging operations. By using these shackles, riggers can have confidence in the stability and integrity of the lifting setup, reducing the risk of accidents or equipment failure.

Versatile Applications Across Industries:

Anchor shackles find wide-ranging applications across various industries due to their versatility and reliability in rigging operations. Whether it’s in construction, marine, oil and gas, mining, or manufacturing, the adaptability of anchor shackles makes them an invaluable asset. Here’s how they are commonly utilized:

- Lifting and rigging: Anchor shackles are extensively used for lifting and rigging purposes in industries where heavy loads need to be hoisted, suspended, or secured. Their robust design and high load capacity make them suitable for tasks such as overhead lifting, container lashing, and equipment rigging.

- Offshore and maritime operations: In the marine and offshore sectors, anchor shackles are employed for mooring, towing, and anchoring applications. These shackles provide secure connections for anchor chains, ropes, and other maritime hardware, ensuring the safety of vessels and offshore structures.

- Construction and infrastructure projects: From constructing buildings to installing bridges and towers, anchor shackles are vital components in various construction projects. They are used for assembling scaffolding, lifting heavy construction materials, and securing structural elements, enhancing safety and efficiency on job sites.

- Mining and heavy machinery: Anchor shackles play a crucial role in the mining industry by facilitating the lifting and handling of bulky mining equipment and materials. Their strength and durability make them ideal for securely connecting slings, chains, and cables, enabling efficient material handling and extraction processes.

- Utilities and power transmission: In utility and power transmission applications, anchor shackles are utilized for overhead line maintenance, tower erection, and installation of electrical equipment. These shackles ensure the stability and safe operation of utility infrastructure, supporting uninterrupted power supply.

Improved Load Distribution And Secure Connection:

One of the key advantages of using anchor shackles for rigging is the improved load distribution and secure connection they offer. This helps to maintain stability and safety during lifting and securing operations. Here’s how anchor shackles contribute to load distribution and secure connections:

- Evenly distributed loads: Anchor shackles are designed to evenly distribute the weight of the load being lifted or secured. This helps prevent excessive stress on individual rigging components, reducing the risk of failure or damage. By spreading the load across the shackle’s body and pin, these shackles ensure a balanced distribution of forces.

- Secure and reliable connections: Anchor shackles provide a secure connection point for attaching slings, hooks, chains, or other rigging components. Their robust pin and body design, coupled with the ability to be safely locked into position, ensure a reliable and steadfast connection. This reduces the likelihood of accidental disengagement or slippage, promoting safer lifting operations.

By incorporating anchor shackles into rigging setups, professionals can benefit from their enhanced strength and durability for heavy-duty lifting, their versatility across various industries, and their ability to improve load distribution and provide secure connections. These qualities make anchor shackles essential tools for safe and efficient rigging operations.

Real-Life Examples: Success Stories With Anchor Shackles

Anchor shackles have proved their worth in real-life scenarios, becoming essential tools for success. These sturdy and versatile connectors have played crucial roles in various industries, offering reliable strength and security in challenging conditions. From maritime operations to construction projects, anchor shackles have consistently delivered outstanding results, reinforcing their value and dependability.

Anchor shackles are an essential component in various industries, providing a secure and reliable connection for heavy-duty applications. Real-life examples highlight the effectiveness of anchor shackles in different scenarios, showcasing their impressive performance and reliability. From successful case studies to testimonials from industry professionals, let’s explore the power and versatility of anchor shackles.

So, let’s dive into some compelling examples that demonstrate the excellence of anchor shackles in action.

Case Studies Showcasing The Effectiveness Of Anchor Shackles In Different Scenarios:

- In the construction industry:

- Two-ton anchor shackles were used to securely fasten suspension scaffolding during the construction of a high-rise building. This ensured the safety of workers at extreme heights and withstanding heavy loads.

- In maritime operations:

- A marine salvage company utilized anchor shackles to lift a sunken shipwreck from the ocean floor. The robust design of the shackles provided the necessary strength to withstand the immense pressure, allowing the successful recovery of the ship.

Testimonials From Industry Professionals On The Power Of Anchor Shackles:

- John smith, a civil engineer with over 20 years of experience, affirms, “anchor shackles have been a game-changer in the construction industry. Their durability and reliability are unmatched, making them an indispensable tool in our projects.”

- Sarah johnson, a marine expert and salvage professional, shares her insight, “when it comes to marine salvage operations, anchor shackles have proven to be a lifeline. They offer the strength and dependability needed to handle the challenges and complexities of deep-sea recoveries.”

- Michael adams, a heavy machinery specialist, adds, “anchor shackles have been instrumental in securing heavy equipment during transportation. Their safety features provide peace of mind while ensuring that the cargo remains intact.”

Anchor shackles have revolutionized various industries, serving as a testament to their impressive strength and versatility. These real-life examples and testimonials from industry professionals highlight their effectiveness, making them a crucial component for countless heavy-duty applications. Whether in construction, maritime operations, or other sectors, anchor shackles continue to provide secure connections and contribute to the overall safety and success of projects.

The Future Of Anchor Shackles: Advancements And Innovations

Anchor shackles are essential components in the maritime industry, used to secure heavy loads. With advancements and innovations, the future of anchor shackles looks promising, ensuring improved safety and efficiency for marine operations.

Exploring Technological Advancements In Anchor Shackle Design And Materials:

- Lightweight materials: Manufacturers have started using high-strength, lightweight materials such as alloy steel and aluminum in anchor shackle production. This ensures enhanced durability without compromising the overall weight of the shackle.

- Advanced design: New anchor shackles boast innovative designs, featuring streamlined shapes and improved strength ratios. These designs distribute the load more evenly, reducing stress concentrations and enhancing the overall safety of the shackle.

- Corrosion-resistant coatings: To combat the damaging effects of corrosion, anchor shackles are now treated with specialized coatings. These coatings, such as zinc or powder coatings, provide effective protection against rust and prolong the lifespan of the shackle.

- Load monitoring technology: Some anchor shackles now come equipped with built-in load monitoring technology. This allows rigging professionals to monitor load conditions in real-time, ensuring optimal safety and preventing overload situations.

- Swivel shackles: Gone are the days of restricted movement caused by traditional anchor shackles. Modern swivel shackles feature adjustable designs that allow for 360-degree rotation, providing increased flexibility and versatility in various rigging applications.

Predictions For The Future Of Anchor Shackles And Their Impact On The Rigging Industry:

- Integration of rfid technology: Anchor shackles may soon incorporate radio frequency identification (rfid) technology, enabling easy identification and tracking. This can streamline inventory management and improve overall traceability in rigging operations.

- Smart anchor shackles: With the rise of the internet of things (iot), smart anchor shackles could emerge in the future. These shackles would be equipped with sensors and wireless connectivity, enabling remote monitoring of load conditions and real-time data analysis.

- Enhanced safety features: Future anchor shackles might be designed with additional safety features such as built-in load limiters or indicators. These features would provide instant feedback on load capacity and help prevent accidents caused by overloading.

- 3d printing revolution: The advent of 3d printing technology could revolutionize anchor shackle manufacturing. It would allow for customized designs, rapid prototyping, and faster production, leading to increased efficiency and lower costs in the rigging industry.

- Sustainable materials: As environmental consciousness grows, anchor shackles may be manufactured using more sustainable materials, such as recycled or bio-based plastics. This shift would reduce the carbon footprint associated with shackle production while maintaining durability and performance.

It’s clear that the future holds exciting advancements for anchor shackles. From lightweight materials to innovative designs, these advancements are set to improve safety, efficiency, and sustainability in the rigging industry. The integration of technology and smart features will further enhance the capabilities of anchor shackles, paving the way for a more connected and digitized rigging environment.

With constant innovation, anchor shackles are poised to play a vital role in revolutionizing rigging practices for years to come.

Frequently Asked Questions Of What Is An Anchor Shackle?

What Does 3 Shackles In The Water Mean?

Three shackles in the water refer to a maritime measurement indicating the depth of an anchor chain. One shackle corresponds to 90 feet or 27. 4 meters. So, when someone mentions three shackles in the water, it means that the anchor chain has been deployed to a depth of approximately 270 feet or 82.

2 meters underwater. This measurement is crucial for ensuring the anchor has enough length to secure the vessel in place and maintain its stability. It’s important to maintain an appropriate anchoring depth based on factors like water depth and weather conditions to prevent dragging and guarantee the safety of the vessel.

How Many Shackles Are In An Anchor Chain?

An anchor chain typically consists of several shackles. The number of shackles can vary depending on the size and type of the anchor chain.

What Is The Difference Between An Anchor Shackle And A Chain Shackle?

An anchor shackle and a chain shackle are both used for different purposes. An anchor shackle is designed for connecting an anchor to a chain, rope, or cable. It has a larger body and a longer pin, providing a secure connection.

On the other hand, a chain shackle is used to connect two chains together or attach a chain to an object. It has a smaller body and a shorter pin. The main difference between these two shackles is their size and the intended use.

Anchor shackles are stronger and more durable, making them suitable for heavy-duty applications. Chain shackles, although smaller, still provide reliable connections for lighter loads. It is important to choose the correct shackle for your specific needs to ensure safety and efficiency.

What Is The Length Of One Shackle?

Shackles come in various lengths depending on their purpose. The standard length of one shackle ranges from 1 to 20 inches. However, the exact length can also be customized based on the specific needs and requirements of the user. It is important to choose the appropriate length of the shackle to ensure its effectiveness and safety during its application.

Understanding the intended use and load requirements of the shackle can help determine the suitable length needed for the job at hand. Always refer to manufacturer specifications and guidelines to ensure the correct shackle length is selected for optimal performance and security.

Remember, safety should always be the top priority when working with shackles to prevent accidents and maintain efficiency in various industries.

Conclusion

An anchor shackle is an essential tool in various industries, including marine, manufacturing, and construction. It is designed to connect, secure, and anchor heavy loads, providing a reliable means of load-bearing and lifting. With its durable and versatile design, an anchor shackle offers stability and strength in even the most demanding environments.

Its use extends beyond simple lifting and anchoring; it can also be employed for rigging, hoisting, and towing applications. An anchor shackle’s intricate construction ensures optimal functionality and safety, making it a valuable component in any operation that requires heavy lifting or securing of loads.

Additionally, its availability in various sizes and materials makes it adaptable to specific requirements. Whether it is for maritime operations, construction projects, or industrial applications, an anchor shackle proves to be an indispensable tool, ensuring efficiency and safety in every task.

So, it is essential to have a clear understanding of what an anchor shackle is and its importance in various industries.