To prevent winch cable from binding, make sure to spool it properly and evenly onto the winch drum. Additionally, regularly inspect the cable for any signs of damage or wear.

Proper tensioning and lubrication of the cable are also important to ensure smooth operation.

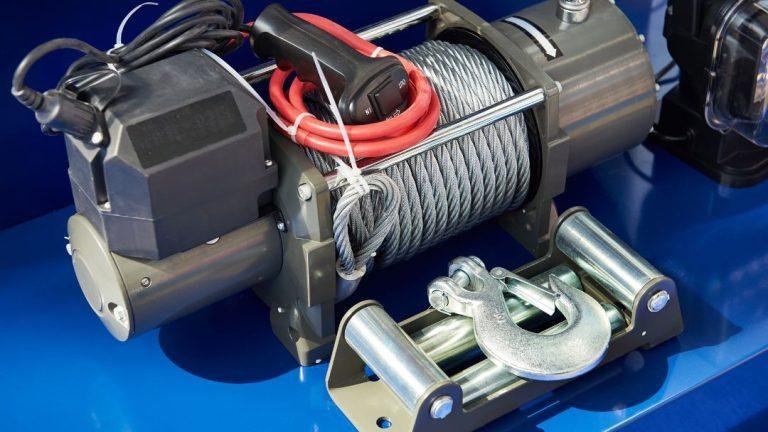

Understanding The Importance Of Preventing Winch Cable Binding

Preventing winch cable binding is crucial for the smooth operation of your winch. Learn how to keep the cable from getting tangled or stuck, ensuring hassle-free and safe towing experiences.

Whether you’re an off-roading enthusiast, a recovery professional, or simply someone who frequently uses a winch, understanding the importance of preventing winch cable binding is crucial. Winch cable binding occurs when the cable becomes entangled or twisted, restricting its movement during operation.

This issue may seem minor, but it can have significant negative effects and even lead to irreversible damage. It’s vital to be aware of the risks associated with winch cable binding and the importance of regular maintenance and prevention techniques.

The Negative Effects Of Winch Cable Binding:

- Decreased pulling capacity: When the winch cable binds, it compromises the pulling capacity of the winch. This means it won’t be able to exert the necessary force to overcome a challenging recovery situation.

- Increased strain on the winch motor: Binding puts excessive strain on the winch motor and other mechanical components. This can result in premature wear and tear, leading to expensive repairs or even complete failure.

- Potential cable damage: Bound winch cables are prone to kinking, fraying, or even breaking. This not only compromises the functionality of the winch but also poses a safety hazard to anyone in the vicinity.

The Risk Of Damage To The Winch And Other Components:

- Overheating: When the winch cable binds, it causes the motor to work harder, generating excess heat. This heat buildup can reach unsafe levels, potentially causing damage to the winch motor, solenoids, and other electrical components.

- Electrical issues: Continuous binding can lead to damage to the winch’s electrical system, including the wiring, switches, and solenoids. This can result in malfunctions, impacting the winch’s performance and reliability.

- Reduced lifespan: Winch components subjected to constant binding are more likely to wear out quickly. This means you’ll have to replace parts or the entire winch sooner than anticipated, resulting in unnecessary expenses.

The Importance Of Regular Maintenance And Prevention:

- Inspections: Regularly inspecting the winch cable for signs of binding is essential. Look for any kinks, twists, or unusual wear patterns. Address any issues immediately to prevent further damage.

- Proper cable spooling: Ensuring the cable is properly spooled onto the winch drum is crucial. Avoid overlapping or crossing the cable, which can contribute to binding. Proper spooling technique will maximize the cable’s lifespan and prevent binding.

- Lubrication: Apply a suitable winch cable lubricant regularly to reduce friction and minimize the chances of binding. This simple maintenance task can significantly extend the life of your winch cable.

- Using a fairlead: Employing a fairlead during winching operations helps guide the cable smoothly onto and off the winch drum, reducing the risk of binding. Make sure to choose the appropriate fairlead for your winch.

Preventing winch cable binding is essential for maintaining a reliable and efficient winching system. By understanding the negative effects of winch cable binding, the risk of damage, and the importance of regular maintenance and prevention techniques, you can prolong the lifespan of your winch while ensuring you’re always prepared for intense recovery situations.

The Root Causes Of Winch Cable Binding

Winch cable binding is often caused by improper spooling, lack of maintenance, a damaged or worn-out cable, or excessive tension. To prevent binding, regularly inspect the cable, avoid overloading the winch, and ensure proper winding to maintain a smooth operation.

Winch cable binding can be a frustrating and potentially dangerous issue when operating heavy machinery or vehicles. Understanding the root causes of winch cable binding is crucial to prevent accidents and ensure smooth operation. In this section, we will identify common causes of winch cable binding and explore the factors that contribute to cable friction and tension.

We will also discuss the effects of dirt, debris, and corrosion on the cable. So let’s dive in!

Identifying Common Causes Of Winch Cable Binding:

- Improper cable winding: When the cable is not spooled evenly and tightly on the winch drum, it can lead to binding during operation. This can occur if the cable is over or under-wound, or if there are overlapping loops.

- Cable misalignment: If the cable is not properly aligned with the winch drum, it can cause binding. This might happen when the cable is pulled at an angle, creating uneven tension and friction.

- Insufficient lubrication: Lack of proper lubrication on the winch drum and cable can result in increased friction and resistance, leading to binding. Regular lubrication is essential to keep the cable running smoothly.

Factors That Contribute To Cable Friction And Tension:

- Overloading the winch: Exceeding the recommended weight capacity of the winch puts excessive strain on the cable, causing increased friction and tension. It is important to check the winch’s load capacity and ensure it is not overloaded.

- Improper cable tension: Insufficient or excessive cable tension can lead to binding. Too much tension can cause the cable to dig into itself, creating friction and potential snags.

- Incorrect cable size: Using the wrong diameter or type of cable for the specific winching application can result in binding. It is essential to choose the appropriate cable size and material based on the load requirements and environmental conditions.

- Winch drum damage: A damaged or worn-out winch drum can cause the cable to bind. Any dents, burrs, or rough surfaces on the drum can create friction points that hinder the smooth movement of the cable.

Effects Of Dirt, Debris, And Corrosion On The Cable:

- Build-up of dirt and debris: Accumulation of dirt, mud, or other debris on the winch cable can cause binding. This build-up creates additional friction and can prevent the cable from spooling properly.

- Corrosion and rust: Over time, exposure to moisture and environmental elements can lead to corrosion and rust on the winch cable. This not only weakens the cable but also results in increased friction and potential binding.

- Lack of maintenance: Neglecting regular maintenance, such as cleaning and inspecting the winch cable, can contribute to cable binding. Routine checks and cleaning will help identify any issues before they escalate.

Remember, identifying and addressing the root causes of winch cable binding is essential for safe and efficient operation. By maintaining proper cable winding, alignment, lubrication, and tension, as well as regularly inspecting and cleaning the cable, you can minimize the risk of cable binding and ensure smooth winching experiences.

Essential Steps For Preventing Winch Cable Binding

Preventing winch cable binding is crucial and can be achieved through essential steps. By regularly inspecting the cable for any signs of damage, lubricating it properly, avoiding sharp angles during operation, and using a fairlead, you can maintain a smooth and efficient winching process.

If you’re an outdoor enthusiast who relies on a winch for your off-road adventures, you know how frustrating it can be when your winch cable gets bound up. Not only does this pose a safety risk, but it can also damage your winch and compromise its performance.

To keep your winch cable from binding, follow these essential steps:

Choosing The Right Winch Cable And Fairlead:

- Opt for a high-quality winch cable that is rated for your specific winch’s weight capacity. This ensures that the cable can handle the load without binding or snapping.

- Consider using a synthetic winch cable, as it is more flexible and less likely to bind compared to steel cables.

- Pair your winch cable with a suitable fairlead that matches its diameter. This helps to guide the cable smoothly onto the drum and prevents binding.

Proper Installation Techniques And Equipment Setup:

- Follow the manufacturer’s instructions when installing your winch and cable. Ensure that all components are securely mounted and aligned correctly.

- Pay attention to the cable’s position on the drum. It should be evenly wound without overlapping or crossing over itself, as this can lead to binding.

- Double-check the alignment of the fairlead to ensure it is straight and properly positioned. Any misalignment can cause the cable to bind during operation.

- Regularly inspect the winch drum and cable for signs of wear or damage. Replace any worn-out parts immediately to prevent binding.

Regular Cleaning And Lubrication For Optimal Performance:

- Clean your winch cable regularly to remove any dirt, mud, or debris that may accumulate. Use a mild detergent and water solution to gently scrub the cable. Rinse thoroughly and allow it to dry completely before use.

- Apply a suitable winch cable lubricant to reduce friction and improve the cable’s flexibility. This helps to prevent binding and extends the lifespan of the cable.

- Pay attention to any rust or corrosion on the winch cable and fairlead. Remove it using a wire brush and apply a rust inhibitor to prevent further damage that could lead to binding.

By following these essential steps, you can keep your winch cable from binding, ensuring smooth and reliable operation during your outdoor expeditions. Remember to choose the right winch cable and fairlead, install everything properly, and regularly clean and lubricate your equipment for optimal performance.

Safeguard your winch and enjoy hassle-free adventures off the beaten path!

Choosing The Right Winch Cable And Fairlead

To prevent winch cable binding, it’s important to choose the right cable and fairlead. Select a cable with proper tensile strength and consider using a roller fairlead to ensure smooth and efficient operation. Regular maintenance and proper installation can also help keep the winch cable from binding.

Understanding The Different Types Of Winch Cables Available:

- Steel cables: Steel cables are the most common type of winch cable and are known for their durability and strength. They are made of multiple strands of steel wire twisted together.

- Synthetic ropes: Synthetic ropes are gaining popularity due to their lightweight and flexibility. They are usually made of high-strength fibers like dyneema or spectra.

- Hybrid cables: Hybrid cables are a combination of steel and synthetic materials. They offer the strength of steel cables with the lightweight properties of synthetic ropes.

- Consider the pros and cons of each type of winch cable to choose the right one for your specific needs and preferences.

Selecting The Appropriate Cable Material And Diameter For Your Needs:

- Determine the weight capacity you require for your winching tasks. This will help you choose the appropriate cable material and diameter.

- Consider the types of vehicles or objects you will be winching. Heavier vehicles may require thicker and stronger cables.

- Steel cables are capable of handling heavier loads compared to synthetic ropes. However, synthetic ropes are lighter and easier to handle.

- Choose a cable diameter that is compatible with your winch drum size. Improper cable diameter can lead to binding issues.

Considering Synthetic Lines For Reduced Binding Risks:

- Synthetic ropes are known for their flexibility and reduced risk of binding. They are less prone to kinking or tangling, resulting in smoother winching operations.

- Synthetic lines have a higher coefficient of friction compared to steel cables, which helps minimize binding risks.

- They are also less likely to develop sharp burrs or fishhooks, further reducing the chance of binding.

- Keep in mind that synthetic ropes may require additional care and maintenance to prevent damage from uv exposure or abrasion.

Importance Of Using A Compatible Fairlead To Minimize Friction:

- A fairlead is a device that guides the winch cable onto the winch drum or off the drum during winching operations.

- It is crucial to use a compatible fairlead to minimize friction and ensure smooth cable movement.

- Steel cables typically require roller fairleads, which reduce friction by allowing the cable to slide freely.

- Synthetic ropes, on the other hand, require hawse fairleads, which are smoother and prevent excessive heat buildup.

- Using an incompatible fairlead can lead to increased friction, binding, and potential damage to the cable or fairlead.

Proper Installation Techniques And Equipment Setup

Learn the proper installation techniques and equipment setup to prevent your winch cable from binding. Follow these guidelines to ensure smooth and effective winching operations.

Ensuring Proper Spooling And Tensioning Of The Cable:

- When installing a winch cable, it’s crucial to ensure that it is spooled correctly onto the winch drum. Here are some key steps to follow:

- Begin by guiding the cable onto the drum evenly, making sure it lays flat and does not overlap or cross over itself.

- As you spool the cable, maintain tension to prevent it from loosely winding or binding. Use a gloved hand to apply gentle pressure on the cable while guiding it onto the drum.

- Avoid over-tightening the cable during spooling, as this could lead to issues such as binding or premature wear.

- By following these proper spooling and tensioning techniques, you can ensure a smooth and efficient operation of your winch.

Properly Aligning The Winch And Fairlead During Installation:

- Achieving proper alignment between the winch and fairlead is essential for the cable’s smooth operation. Consider the following during the installation process:

- Mount the winch securely to a strong and stable surface, ensuring that it is aligned parallel to the fairlead.

- Position the fairlead in a way that allows the cable to feed onto the drum without any obstructions or sharp bends.

- Check for proper alignment by operating the winch in both in and out modes while observing the cable’s entry and exit from the fairlead.

- Proper alignment between the winch and fairlead guarantees a straight cable path, minimizing the chances of binding, damaging the cable, or compromising its strength.

Understanding The Importance Of Correct Anchor Points And Angles:

- Anchor points and angles play a crucial role in keeping the winch cable from binding. Here’s what you need to know:

- Identify strong anchor points that can handle the load and provide a reliable pulling position. Tree trunks, rock formations, or built-in winch points on vehicles can serve as solid anchor options.

- Consider the angle at which the cable is being pulled when selecting the anchor point. Smaller angles, preferably less than 30 degrees, are more favorable, as they reduce the risk of binding and increase pulling efficiency.

- When using a snatch block to change the pulling direction, ensure that the block is correctly aligned with the anchor point and the fairlead to prevent cable binding.

- By understanding anchor points and angles, you can make informed decisions that promote effective winching while avoiding potential binding issues.

Remember, proper installation techniques and equipment setup are vital to prevent winch cable binding. Ensure correct spooling, tensioning, alignment, and anchor point selection to optimize your winching experience.

Regular Cleaning And Lubrication For Optimal Performance

Regular cleaning and lubrication are essential for keeping the winch cable from binding and ensuring optimal performance. By regularly maintaining your winch, you can prevent the cable from getting tangled or stuck, allowing for smooth and efficient operation in all your towing and pulling tasks.

Regular cleaning and lubrication are essential for maintaining the performance and longevity of your winch cable. By following these simple steps, you can prevent binding, reduce friction, and ensure smooth cable movement.

Removing Dirt, Debris, And Corrosion From The Winch Cable:

- Inspect the winch cable for any signs of dirt, debris, or corrosion.

- Gently brush off any loose dirt or debris using a soft-bristle brush.

- Use a mild detergent mixed with water to remove stubborn dirt or grime.

- Rinse the cable thoroughly with clean water to remove any residue.

- Dry the cable completely using a clean towel or air drying.

Using Suitable Cleaning Agents And Techniques To Prevent Damage:

- Avoid using harsh chemicals or abrasive cleaners, as they can damage the inner strands of the winch cable.

- Opt for mild detergents or specific cable cleaning solutions recommended by the manufacturer.

- Follow the instructions provided with the cleaning agent to ensure proper usage.

- Apply the cleaning agent to a sponge or cloth and gently scrub the cable.

- Rinse thoroughly to remove any residual cleaning agent.

Applying Lubrication To Reduce Friction And Enhance Cable Movement:

- Select a lubricant specifically designed for winch cables, such as a silicone-based lubricant or a specially formulated winch cable grease.

- Apply a small amount of lubricant directly onto a cloth or rag.

- Rub the lubricant onto the cable, ensuring even coverage.

- Pay extra attention to areas where the cable tends to bind or experience friction.

- Wipe off any excess lubricant to avoid attracting dirt or debris.

Regular cleaning and lubrication of your winch cable will not only help prevent binding but also extend its lifespan and maintain optimal performance. By incorporating these simple maintenance tasks into your routine, you can ensure that your winch operates smoothly and efficiently when you need it the most.

Additional Tips And Tricks To Prevent Winch Cable Binding

Prevent winch cable binding with these useful tips and tricks. Keep the cable in good condition by regularly lubricating it, avoiding sharp bends, and using a roller fairlead. Additionally, always spool the cable evenly on the drum to prevent binding and ensure smooth operation.

To ensure the smooth and effective operation of your winch, there are several additional tips and tricks you can employ to prevent winch cable binding. By following these guidelines, you can enhance the safety and longevity of your winch cable, while also minimizing the risk of accidents or damage.

Here are some key strategies to consider:

Avoiding Excessive Cable Tension And Overloading:

- Be mindful of the maximum load capacity of your winch and always adhere to the manufacturer’s guidelines. Exceeding the recommended weight limit can put undue stress on the winch cable, increasing the likelihood of binding.

- Prioritize even load distribution to prevent overloading a specific area of the cable. Distribute the weight across multiple anchor points or use pulleys to achieve balanced tension, reducing the strain on the cable.

- Keep an eye on the tension during winching operations. Avoid applying excessive force to the cable, as it can lead to binding. Utilize a load gauge or tension measuring device to monitor the tension and adjust accordingly.

Practicing Proper Winching Techniques And Usage:

- Ensure that the winch cable is winding onto the drum evenly. Uneven winding can cause the cable to bind or become entangled, leading to operational issues.

- Avoid sharp angles, kinks, or twists in the cable during winching. These irregularities can contribute to binding and hinder the cable’s smooth movement.

- Use a cable damper or blanket when winching in situations where the line might snap or break. This safety measure reduces the risk of cable whipping and binding in the event of a failure.

Regular Inspections To Identify Signs Of Wear And Damage:

- Perform routine visual inspections of the winch cable before each use. Look for any fraying, kinks, or other visible signs of wear that could potentially lead to binding.

- Check the condition of the drum and fairlead, ensuring they are free from dirt, debris, or corrosion that may obstruct the cable’s movement.

- Lubricate the winch cable regularly to reduce friction and maintain smooth operation. Use a silicone-based lubricant designed specifically for winch cables.

By following these additional tips and tricks, you can minimize the chances of winch cable binding and prolong the lifespan of your winching equipment. Remember to always prioritize safety and adhere to proper maintenance practices to ensure reliable and efficient winching operations.

Frequently Asked Questions Of How To Keep Winch Cable From Binding

Should I Lube My Winch Cable?

Yes, you should lubricate your winch cable regularly. Lubrication helps prevent rust and corrosion, as well as reduces friction between the cable and the winch drum. This ensures smoother operation and extends the lifespan of your winch cable. Regular lubrication also helps to maintain the cable’s flexibility and prevents it from becoming stiff or breaking.

To lubricate the winch cable, apply a thin layer of winch-specific lubricant along its entire length, including the connection points to the winch drum and hook. Be sure to clean any dirt and debris off the cable before applying the lubricant.

Regular maintenance and lubrication of your winch cable will help keep it in optimal working condition and ensure reliable performance when you need it.

How Do You Lubricate A Winch Cable?

First, ensure the winch is not running and the cable is not under tension. Apply a lubricant designed specifically for winch cables. Spray or drip the lubricant along the length of the cable, making sure to cover all surfaces. Then, use a rag or brush to distribute the lubricant and work it into the cable strands.

Pay extra attention to any areas with visible wear or damage. Once the cable is thoroughly coated, wipe off any excess lubricant. Regularly inspect the cable for signs of wear or corrosion and repeat the lubrication process as needed. Remember, proper lubrication is essential for maintaining the performance and lifespan of your winch cable.

What Do You Spray On A Winch Cable?

To protect the winch cable, it is recommended to spray it with a lubricant. This helps prevent rust and corrosion, and ensures smooth operation. Use a high-quality, silicone-based spray or a dedicated winch cable lubricant. Apply the spray evenly along the entire length of the cable, paying attention to any exposed or vulnerable areas.

Regularly spraying the cable will extend its lifespan and maintain optimal performance. Remember to wipe off any excess spray and keep the cable clean and free from dirt or debris. Proper maintenance of the winch cable is essential for safe and efficient operation.

How Do You Unwind A Stuck Winch Cable?

To unwind a stuck winch cable, follow these steps: 1. Stop using the winch immediately when you notice the cable is stuck. 2. Inspect the cable for any entanglements or obstructions that may be causing the problem. 3. Slowly and carefully reverse the winch to apply tension in the opposite direction.

4. Avoid jerking or yanking the cable as it could worsen the situation. 5. If the cable remains stuck, use a winch line dampener or a heavy blanket to cover it for added safety. 6. Seek assistance from a professional if you’re unable to resolve the issue on your own.

7. Once the cable is free, inspect it for any damage or wear and consider replacing it if necessary. Remember to prioritize safety and take all necessary precautions when working with winch equipment.

Conclusion

Keeping your winch cable from binding is crucial for smooth operation and preventing potential accidents. By following the steps outlined in this blog post, you can ensure that your winch cable remains in optimal condition and functions properly. Remember to regularly inspect and clean your winch cable, lubricate it with a suitable lubricant, and replace it if necessary.

Properly spooling the cable onto the winch drum and using a snubber can also help prevent binding. Additionally, always exercise caution when using your winch and never exceed its rated capacity. By taking these preventative measures, you can extend the lifespan of your winch cable and enjoy safe and hassle-free winching adventures for years to come.